CNC Machining Case 3

Case Study

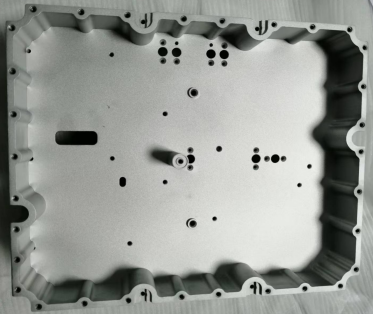

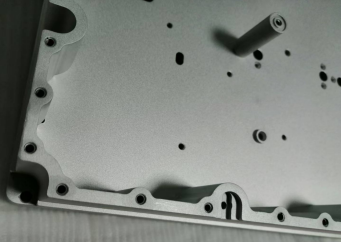

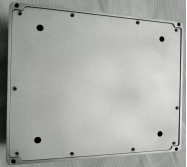

Project Name: AL6061 Enclosure

Client Location: Germany

Product Application: Power Control Enclosure

Technical Specifications:

Material: AL6061

Dimension: 350 x 280 x 110 mm

Hole Tolerance Grade: H6

Threading: M4 6H

Appearance Requirements:

Surface Treatment: Sandblasting with 100# grit

Anodizing: Natural color

Surface Quality: Free of burrs and scratches

Production Details:

Quantity: 60 sets

Lead Time: 20 days

Production Process: 3-axis CNC milling, 100# glass bead blasting, surface cleaning, anodizing

Project Collaboration:

After evaluating the cost and technical requirements, we implemented a strategy using 3-axis CNC milling with high-precision fixtures. This approach fully met the client's demands for technical specifications, appearance, and lead time. Following a thorough supplier assessment, the client ultimately chose to collaborate with us.

Production Control:

We adhere to ISO9001 standards, conducting pre-production analysis and managing progress throughout the production process to ensure timely delivery.

Quality Assurance:

Given the specific product characteristics and tolerance requirements, we use equipment such as projectors, CMM (Coordinate Measuring Machines), and thread gauges to verify that all parts meet the required quality standards.

Our Services:

We provide continuous support throughout the production process, keeping the client updated with real-time progress.

We closely monitor the logistics during shipment, ensuring timely delivery.

After delivery, we follow up to ensure the client's satisfaction with the product.