CNC Machining Case 1

Case Study

Project name: Case study of customized processing of motorcycle front and rear wheel hubs

Material used: aluminum alloy 6061 T6

Cooperation quantity: 3 sets Total 6

Production process used: CNC turning CNC milling Electrostatic spraying

Production cycle: 33 days

About the product and design requirements:

The product is used in the design of high-speed motorcycle racing wheels, which requires a higher speed than ordinary wheels, so the dimensional precision of the product is very high error range of 0.008-0.01mm, the true roundness requirement is as high as 0.015mm, the part of the machining process for any dimensional deviation and deformation of the product, will bring about a serious bias on the future prototype test.

Design Analysis:

Because the customer is a professional product designer, the customer's well-designed product does not need us to make any changes and needs to be produced exactly according to the design drawings. The material chosen by the customer is AL6061. Our professional prototyping technology can well meet the customer's needs.

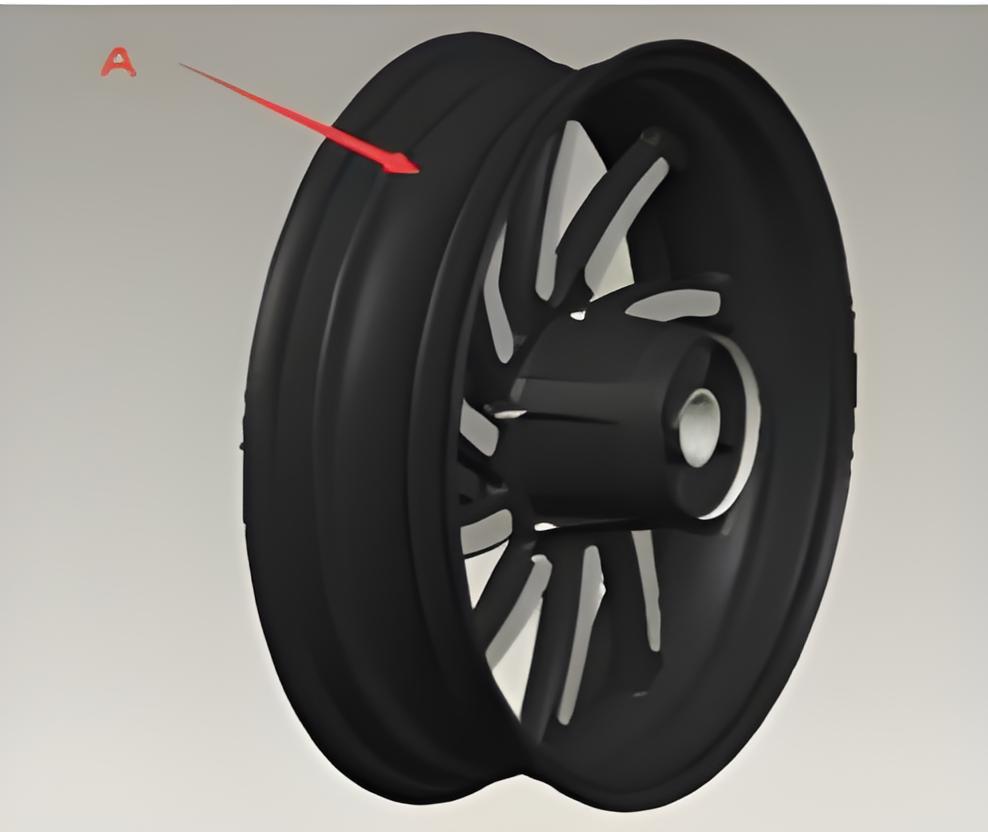

The center position indicated in the diagram requires a high-precision rolling bearing (accuracy: 0.005mm) to ensure a tight fit. The dimensional accuracy of the center and the outermost edge must be 0.008mm to ensure the wheel rotates at high speeds without wobbling.

The shape and dimensions of the tire shown in the diagram must meet strict requirements to prevent deformation during processing. Controlling dimensional tolerances is crucial. Any deformation or errors will directly affect the fit between the tire and the wheel.

To enhance the appearance of the product, the parts require electrostatic spraying. The area marked in white on the diagram needs to maintain the natural color of the aluminum alloy, with a focus on achieving a clear and aesthetically pleasing boundary between the black spray and the natural color. Through analysis, we utilize our unique masking and spraying techniques to meet the high standards required by our customers.

Testing Methodology:

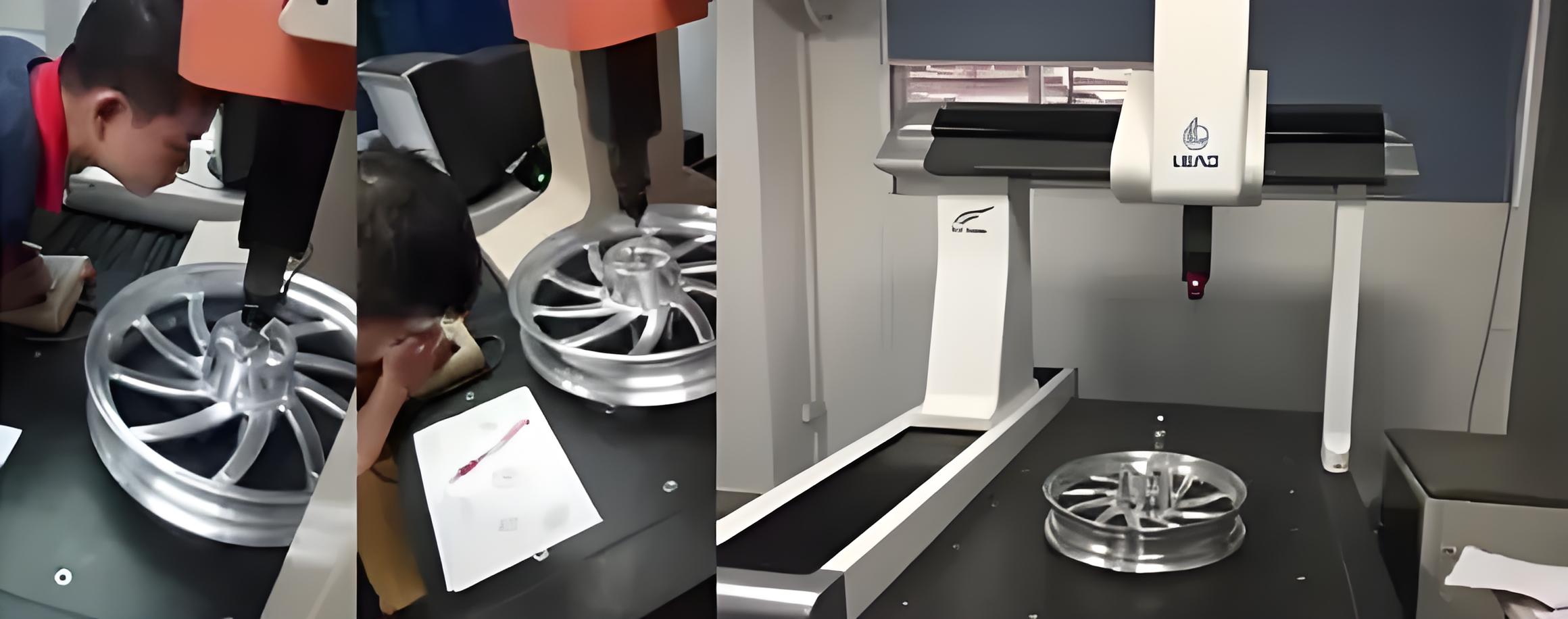

Strict 3D coordinate testing is required to verify the dimensional accuracy indicated on the drawings. Not a single deviation is permissible, ensuring 100% compliance with customer design requirements. A total of 300 dimensions need to be tested.

About the Project:

Through cost analysis and process evaluation, we developed a strategy involving CNC turning, complemented by CNC milling and high-precision fixture clamping. After comprehensive supplier evaluations, the customer ultimately chose to collaborate with us.

CNC turning machining

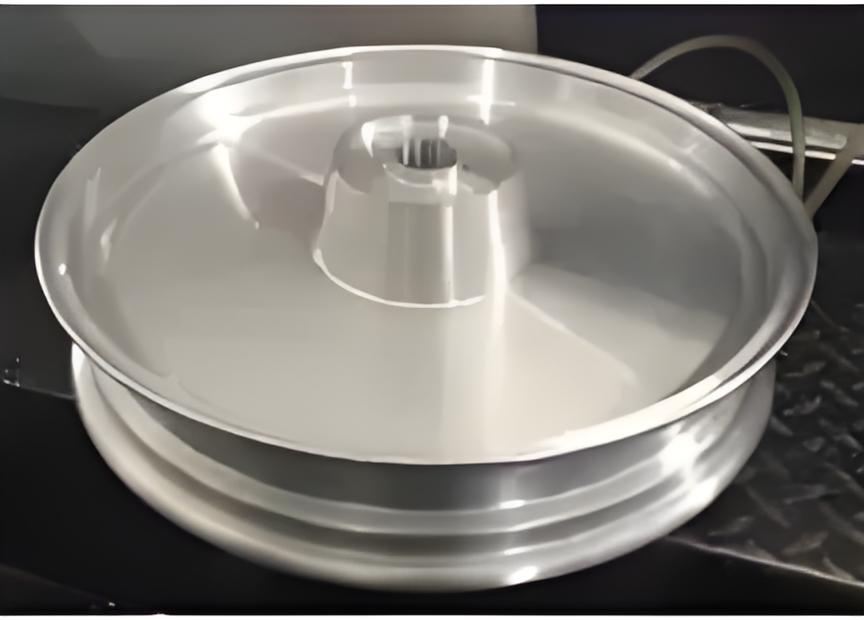

The first step is to use CNC turning machining to ensure the overall dimensions of the center and outer circle.

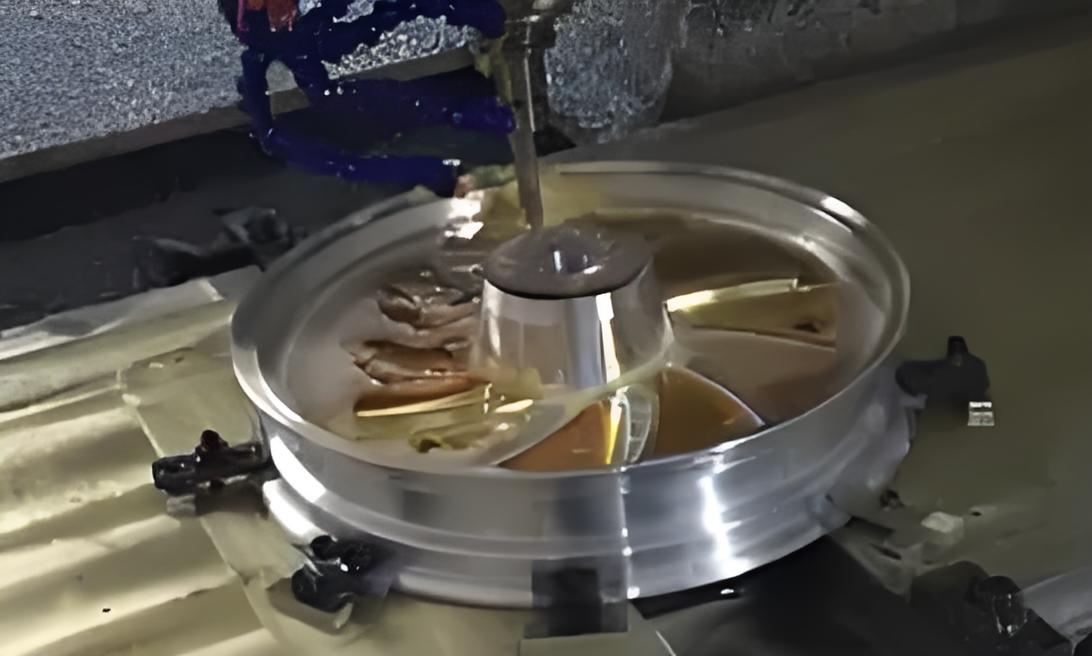

CNC milling machining

Large-scale CNC milling machining technology combined with high-precision fixture clamping ensures that the product remains free from deformation during clamping. It's crucial to pay attention to the center position as it directly impacts the final quality of the entire product.

Paying attention to details is also a key factor in maximizing customer satisfaction, and we have very strict requirements for font treatment on our products.

Quality Inspection

Strict quality inspection is an essential part of our work. It's also a critical process in determining the quality of our products. We carefully inspect each critical dimension to ensure customer satisfaction and to achieve the highest level of service satisfaction from our customers.

Experience:

Having professional expertise and strict precision control are essential to producing final products that satisfy customers. We take pride in every part we manufacture. You will be proud to have these custom parts. If you have a project, please contact us promptly to customize a solution that meets your needs.