CNC Machining

CNC Machining Service

Custom CNC Machining Solutions

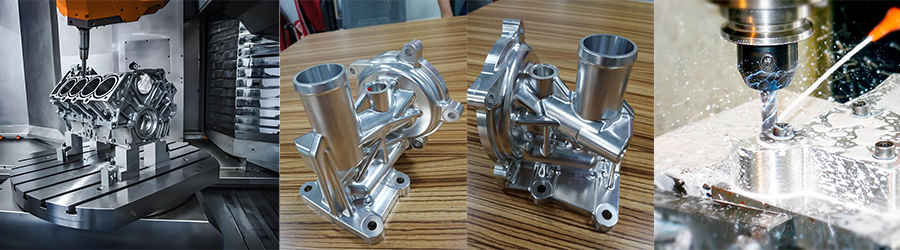

Lauens offers custom CNC parts machining services for your specific manufacturing needs in accordance with the ISO 9001:2015 management system, utilizing our precision mill-pin, turn-pin CNC machinery and equipment.

Whether you require a one-time prototype or large-scale mass production, we ensure the precision and quality of every part we produce..

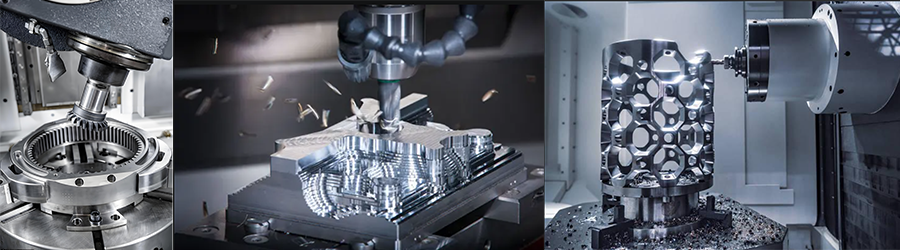

What is CNC machining?

CNC machining is the use of computer-controlled milling or turning pin precision equipment to write specific programs to control the path of the tool cutting pins through the customer's material requirements, dimensional accuracy, and surface finish of the part to obtain the designed part. This technology provides higher speed, part stability, precision and accuracy. It also allows for more flexible production scheduling to meet customers' varying volume and lead time requirements.

Advantages of Lauens CNC Machining.

Lauens has specialized types of CNC production equipment, including 3-axis CNC 4-axis CNC 5-axis CNC and mill-turn CNC machining services, no matter the structure of simple or complex parts have the appropriate CNC machines to match.

Our team of engineers have extensive experience in production evaluation, and will develop a professional FMEA assessment for your upcoming parts, identifying the potential machining risks of the parts before production to ensure consistent quality.

Lauens has a production service team with nearly 20 years of experience, which can quickly develop a perfect machining solution for each of your parts, reducing your communication costs.

Lauens' Management:

The dimensional accuracy of the parts we manufacture can reach a minimum precision of 0.01mm, with deformation controlled to a

minimum of 0.01mm.

Our equipment can produce parts up to 2 meters in length, using materials such as aluminum alloys, various plastics, stainless steel,

and titanium alloys.

Our professional QC team designs inspection plans for parts, utilizing CMM inspection, optical projectors, height gauges, thread

gauges, and plug gauges to ensure quality compliance.

We strictly manage lead times according to ISO9001 standard processes, ensuring the accuracy of delivery times.

Quality of Lauens

We have many years of professional QC staff to design the inspection program for the parts, using three-dimensional inspection, optical projector, height gauge, dental gauge, plug gauge and other inspection equipment, to ensure the quality of qualified.

Lauens' Flexibility:

Our production can be customized to your standards to meet diverse requirements.

We offer machining services regardless of quantity, from single units to standardized mass production.

Lauens' Assurance Services:

Our business team provides seamless service follow-up for your purchase, from production timelines to shipping schedules and post-delivery usage. Any issues will be promptly addressed and resolved.

Industries in which Lauens' CNC machining services are utilized

With years of experience in CNC machining, we have proudly served numerous industries. Our key industry applications include:

1.Transportation Industry

2.Medical Industry

3.Scientific Research Equipment Industry

4.AI Robotics Industry

5.New Energy Vehicle Industry

Material classification for CNC machining

We use a variety of materials, including:

Plastics: ABS, PP, PMMA (acrylic), PC, POM (Paraformaldehyde Resin), PBT, Nylon (PA), PU, RESIN, PEEK, PE, PTFE (Teflon), G-10 (FR-4), PVC, EVA, EPS, and so on.

Hardware: Stainless Steel, Steel, Aluminum Alloy, Brass, Copper, Iron Alloy, Magnesium Alloy, Tool Steel, Alloy Steel, Tungsten Alloy, etc.