Case Study

Project Name: Jewelry Inspection Magnifier

Material: PMMA

Quantity: 30 sets (30 pieces total)

Manufacturing Process: CNC turning, CNC milling, surface electroplating

Production Cycle: 15 days

About the Product and Design Requirements:

This product is used to measure the luster of jewelry based on the principles of light refraction and reflection. Therefore, the requirements for the inner and outer surfaces of the product are as follows:

1.Complete all mirror surface processing.

2.The surface must be free of any scratches.

3.Each product's angle dimensions must be precisely machined, and the material's light transmittance must be over 95%. The key technology is the localized electroplating of the product.

Design Analysis:

Let's take a close look at the design.

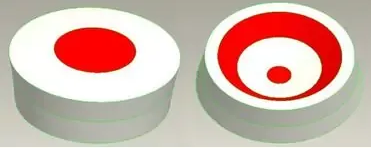

1.The customer requires full reflective mirror electroplating on the white parts. The red areas need to be completely transparent. To meet these custom specifications, we have selected PMMA as the material. Our polishing and localized electroplating techniques, combined with our professional prototype manufacturing technology, ensure we can effectively satisfy the customer’s needs.

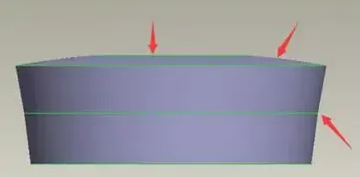

2.The diagram indicates slight angles. If the processing does not meet the surface requirements and results in blurred surface boundaries, the final product will deviate from the original design vision, which is undesirable for the customer. Our technical experience in handling these details ensures we fully meet the customer's expectations.

Inspection Method:

Our QC department uses a coordinate measuring machine to measure the actual dimensions of the processed parts, ensuring the consistency of the entire batch.

About the Project:

The key lies in understanding the critical dimensions of the customer's product and the ultra-high requirements for the product surface. Our hand-finishing team has professional technical support. Through sample production and testing, we ensure customer satisfaction.

CNC Turning:

We use CNC turning to ensure the perfection of various detailed features.

Post-Processing:

Polishing is a crucial step in the entire product processing process. We divide it into four stages to ensure the consistency of surface gloss. Finally, mirror grinding is performed, and the entire process must be seamlessly integrated.

The final step is electroplating. The customer requires partial electroplating. We use the immersion method for electroplating, adding production line technology between the electroplated and transparent surfaces to ensure a perfect connection between them.

Experience:

We take pride in every part we produce. You will take pride in owning these custom parts. During production, we carefully summarize our experiences to provide you with perfect customized services that meet every customer's needs. When you have solutions or customization needs, we are always ready to provide you with tailor-made, perfect services.

Categories

Latest News

Contact Us

Contact: Shenzhen Lauens Technology Co., Ltd.

Phone: +86 18392576823

E-mail: contact@lauens.com

Whatsapp:8618392576823

Office Add: No. 8, Guangyuan 4th Road, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen